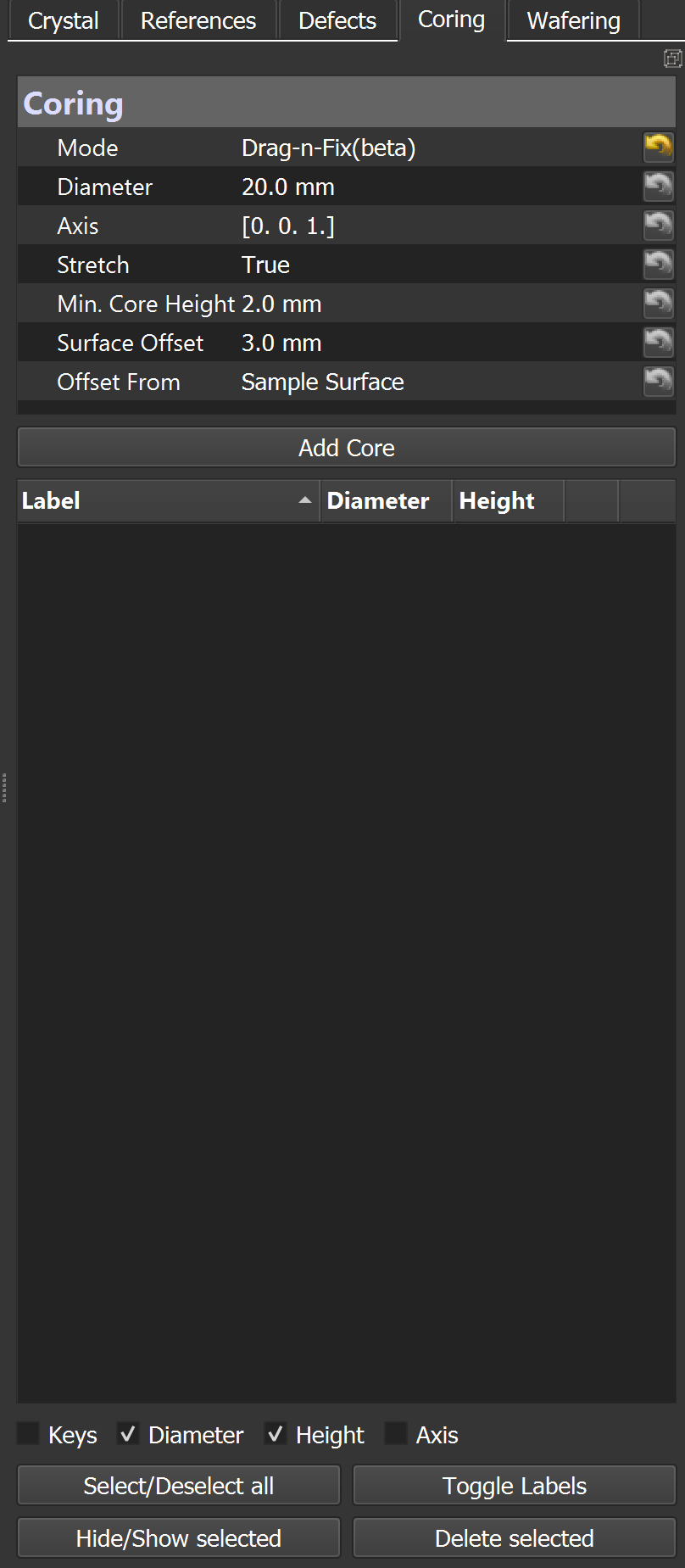

Chapter 5: Coring Tab

The Coring Tab in Yield is used to define and manage cylindrical cores for cutting and further processing. It allows users to create cores automatically or manually and adjust key parameters related to core size, position, and orientation. Here’s a breakdown of the key features and options available:

Coring Modes

The Automatic Mode lets you quickly create cores based on predefined settings. This calculates and adjusts the cores’ parameters without needing manual input.

Using the Drag & Fix Mode, add cores to the crystal. Simply select the desired position on the crystal where you want the core to be located, and “drag” the tool to adjust its size or orientation. Each core represents a cylindrical section that will be cut during the coring process.

Core Parameters

The following parameters allow fine-tuning of the cores based on your requirements:

Diameter: Specify the diameter of the core to be created.

Cut Below: Defines the depth below which the cut should not proceed (in mm).

Cut Above: Sets the height limit above which the cut should not extend (in mm).

Surface Offset: Adjusts how much of the core surface should be offset from the base sample surface (in mm).

Offset From: Choose whether the offset is calculated from the sample surface or another reference point.

Core Management Section

Add Core: This option allows you to manually add a core at a specific position. Once a core is created, the following properties can be edited:

Label: A unique identifier for the core.

Diameter: The size of the core in millimeters.

Height: The height of the core in millimeters.

Color: The visual color assigned to the core in the model.

Core Visibility and Selection

The Coring Tab provides checkboxes and buttons to manage the visibility and selection of cores and their properties:

Keys: Displays key labels for easy reference in the model.

Diameter: Shows the diameter of the core.

Height: Shows the height of the core.

Axis: Highlights the axis along which the coring takes place.