Welcome to Scientific Visual’s documentation!

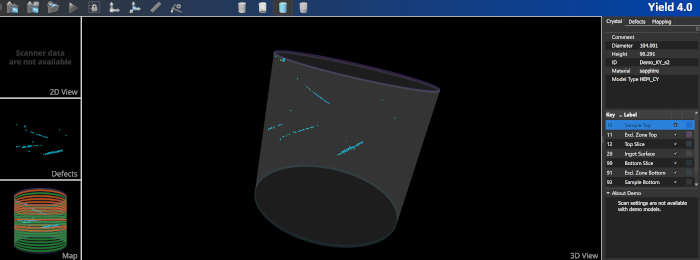

Scientific Visual offers quality control scanners that visualise volume defects, such as bubbles, cracks and cloudiness, in raw crystals.

They identify imperfections in pre- and post- polished sapphire, ruby, glass, fluorites, SiC and a wide array of semiconductor crystals. Our scanners ensure that only materials meeting the highest quality standards enter the costly processing stream. Quality grading can be tailored to each customer’s specific requirements.

Scientific Visual serves three key markets: watch, semiconductor and smartphone manufacturers.

Software Suite 4

- Yield-Pro Software

Cross-platform tool for viewing 3D models produced by Scientific Visual equipments.